The FAA has set September 2022 as its target for issuing a draft rule on mandating safety management systems for repair stations and several other types of organizations and expects a final rule to come out in the first quarter of 2024.

“Safety Management Systems [SMS] for these organizations will help ensure a holistic, proactive assessment of whether the combination of design, procedures and training will support effective safety performance,” the agency told the U.S. Transportation Department Office of Inspector General (OIG) in feedback on a report. “FAA strongly promoted voluntary SMS for design and manufacturing organizations, and will continue to do so while the rulemaking is in progress.”

The exchange came during the OIG’s production of a report on the FAA’s certification of the Boeing 737 MAX. The final report, released in late February, contained 14 recommendations that focus on revamping certification rules and guidance, strengthening its Organization Designation Authorization (ODA) program and adding human-factors expertise in certification.

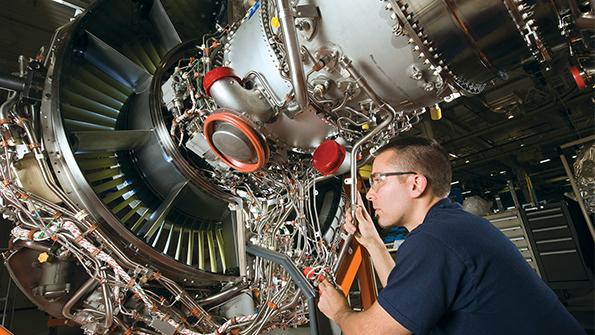

One of the recommendations is to require SMS for certain organizations regulated under Parts 21, 91, 135 and 145. Among the challenges the initiative will face, particularly with repair stations, is tailoring its requirements to the variety of organizations they will cover. The FAA’s 5,000 certified repair stations range from mom-and-pop shops to billion-dollar operations with multiple locations. Many have contracts with customers—notably airlines already required to have SMS in place—that mandate SMS-like protocols. Factoring all of this into a rule will be difficult, says Sarah MacLeod, head of the Aeronautical Repair Station Association (ARSA). That, she says, likely translates into an elongated timeline.

“I think it’s going to be five years before the final rule for all repair stations,” she said at ARSA’s recent annual conference. The last major U.S. repair station rule change—a revamp of Part 145—took over seven years, she added.

Hurdles could also arise for the FAA in justifying some elements of an SMS mandate. The 2007 Part 145 revamp left out a major element—quality assurance programs meant to function as internal auditing procedures that many organizations already have—the FAA included in the draft. The reason? The rule-writers could not make the anticipated benefits justify the costs.

The agency “is going to have to be very careful about how it navigates the Administrative Procedure Act and . . . [related] executive orders,” MacLeod said, referring to the U.S. government’s agency guidelines on crafting new rules. “We just need to make sure that we’re doing this right and moving it forward correctly.”

ODA program changes are on the way as well. Among them is new guidance that governs working on behalf of both the applicant and the FAA on the same certification project by January 2024 and “internal controls” that help prevent interference with ODA unit members by June 2025, the FAA told the OIG.

Another issue tackled in the report is the FAA’s Changed Product Rule, which includes Parts 21.19 and 21.101 and permits certifications to older standards for new products based on existing designs. The FAA has targeted late 2025 for issuing updated Changed Product Rule regulations and guidance.

“While FAA’s regulations do not contain a limit on the number or types of exceptions that can be granted—as long as exceptions meet certain requirements—agency officials stated that one of their lessons learned from the certification of the MAX is the need to limit the exceptions that it grants,” the OIG report said.

For example, the European Union Aviation Safety Agency (EASA) has raised concerns with the 737 MAX’s antiquated flight-crew alerting functions, which “follows the architecture and cockpit philosophy established early in the 737 design history,” EASA said. The FAA’s agreement to apply the Changed Product Rule meant Boeing did not have to fully comply with FAA rules updated in 2011 that matched existing EASA standards. Boeing is reviewing the issue to satisfy EASA’s concerns.

The agency also plans to modify system safety assessment (SSA) guidance contained in Advisory Circular 25.1309. The document “was last updated in 1988 and relies heavily on qualitative analysis and engineering judgment to identify and classify failure conditions and determine how to assess them for regulatory compliance,” the OIG said.

Modifying it aligns with an NTSB recommendation issued in September 2019 linked to the two fatal 737 MAX accidents that led to a 21-month grounding and the ongoing FAA certification scrutiny (AW&ST Nov. 23, 2020, p. 16).

“FAA is taking numerous steps to reform its certification process, including the Changed Product Rule, and to update its guidance to ensure a more holistic assessment of aircraft design changes,” the agency wrote in its formal response to the OIG report. “In addition, FAA is adjusting its processes to improve the flow of information during the certification process. Working on aircraft certification matters with our international partners does take time, as such efforts can require rulemaking and coordination not only in the United States, but also across foreign regulatory frameworks to achieve and maintain harmonization.”