Dutch Consortium Pursues MRO Sustainability Through Digitalization

The Netherlands Aerospace Centre is researching how techniques such as robotic inspections could be used to improve efficiency and sustainability within MRO.

A research and development consortium in the Netherlands is pursuing the use of innovative technologies in MRO and other segments of aviation to make the industry more sustainable.

Comprised of 12 partners from across the aviation, technology and academic sectors, the BrightSky consortium is researching how technologies could improve efficiency and sustainability across aviation operations. Within MRO, it is focused on developing innovative inspection and repair techniques, digital simulation training, and digital tools based on predictive maintenance and remote inspection techniques to drive decision making. The consortium is also researching autonomous airside operations and airport security checks.

Two of the partners leading the MRO-focused projects are the Netherlands Aerospace Center (NLR) and JetSupport, a Part 145 MRO focused on business jets. According to Ton van Deursen, founder and CEO of JetSupport, the goal is to make the aviation industry smarter and more sustainable while reducing its labor intensity.

In light of the industry’s workforce shortage, van Deursen says MROs “are forced to become smarter by applying innovation to the full extent to make sure that our current and future staff will be supported.”

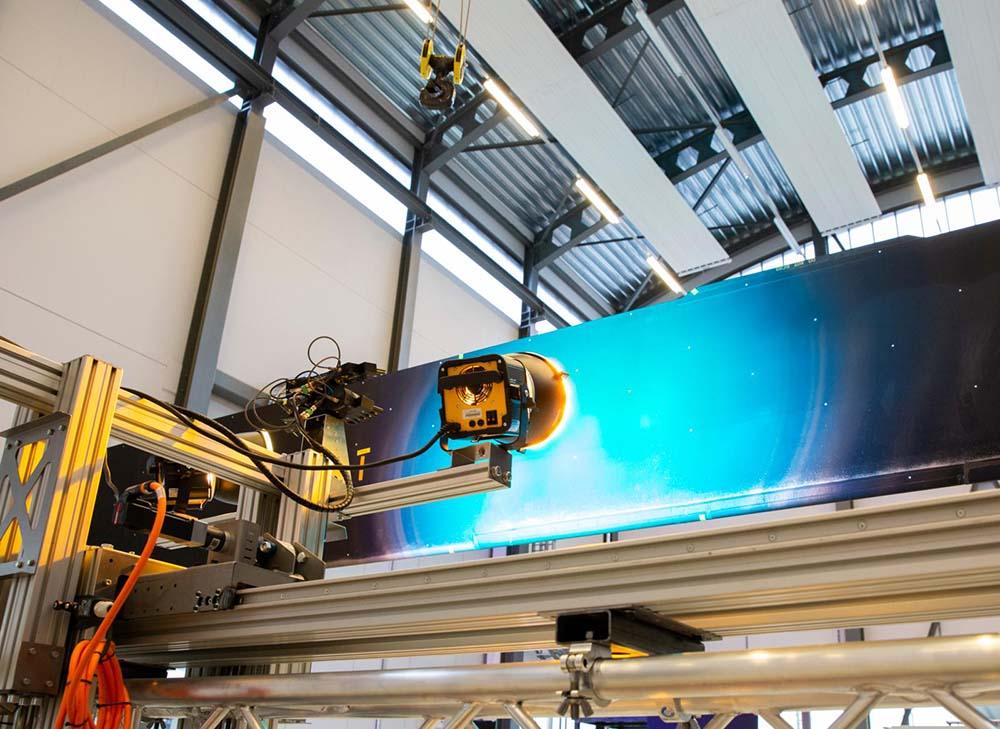

One way in which the consortium is working toward this is through using automated, digital inspections to support technicians in making maintenance decisions. Last month, JetSupport introduced an automated scanner prototype developed by NLR at its hangar facility, which can detect sub-surface defects. According to Peter Ort, executive policy advisor at JetSupport, the technology is low cost and can significantly reduce inspection time, which “could have a huge impact on the downtime.” The consortium is researching a variety of different scanning techniques that can be used to assess damage and the need for repairs on composites, metal or any surface used in an aircraft.

The partners are also working with KLM to expand the scope of these inspections to engine parts. NLR is researching the use of autonomous inspection robots for engine-related defects, such as cracks, and it expects to be involved in the use of cold-spray techniques for engine repairs. The airline’s objective is to develop a generic inspection and repair robot for a range of engine parts.

Since it is more difficult for a large airline to ground aircraft for this type of research and development, JetSupport’s position as a business aviation MRO is proving beneficial. According to van Deursen, “JetSupport has more access to aircraft in which you can do a living lab to try out these new technologies. The cooperation is unique as such, where we have found ourselves [applying] these new technologies on-site.”

Aircraft availability also ties into the motivation behind the consortium’s work in creating simulators for training. “For training we are working on building a simulator for maintainers because we see the occurrence of maintenance incidents is not high enough that they can stay current,” says Ort. “But by introducing a simulator, you can have more simulated incidents. That way [maintainers] will stay current.”

Ort says a training simulator could also help the MRO industry deal with its pandemic-related exodus of staff. “On the other end, you can also use it as a facility to keep people who are currently employed elsewhere [e.g. those who left the industry during the pandemic] current in aviation maintenance knowledge, so when they come back they are still able to pick it up really quickly,” he says.

According to van Deursen, this simulated training will play a crucial role in the consortium’s sustainability focus. For example, he says a company that works with many aircraft types can retain knowledge about how to maintain them without needing to access the aircraft themselves. In addition to reducing the need to move aircraft and staff around, van Deursen says “we can do all this simulation without starting an engine and burning fuel.”

Ort says BrightSky is hoping to implement many of its technologies by 2030—a goal that is significantly sooner than the 2050 time frame many aviation stakeholders are targeting for net-zero carbon emissions. He says the consortium also intends to look to other industries, such as automotive or maritime, for opportunities to mutually collaborate or for other innovation techniques that could be used in aviation.