Developing MRO capabilities for hydrogen-powered aircraft is an emerging area of interest in the aftermarket.

Hydrogen and Electric Propulsion

As aviation industry sustainability deadlines loom, hydrogen- and electric-propulsion initiatives are beginning to gain traction. Electric- and hydrogen-propulsion OEMs such as ZeroAvia, MagniX and Universal Hydrogen are working with engineering partners such as Cranfield University and AeroTEC to retrofit aircraft with these greener propulsion technologies.

MRO specialists are also beginning efforts to study how these technologies will affect maintenance and ground operations. Lufthansa Technik is using a decommissioned Airbus A320 as a field laboratory to research procedures required for handling liquid hydrogen in a maintenance environment. NLR is also exploring converting an aircraft to hydrogen propulsion, and it is beginning efforts to research maintenance requirements for the necessary components, hydrogen systems and electrical systems.

MROs and aftermarket companies are building up maintenance infrastructure for electric vertical-takeoff-and-landing aircraft as well.

Robotics

The MRO industry has been exploring the use of robotics in maintenance for many years, but several recent and upcoming developments show the technology is still attracting plenty of interest and investment.

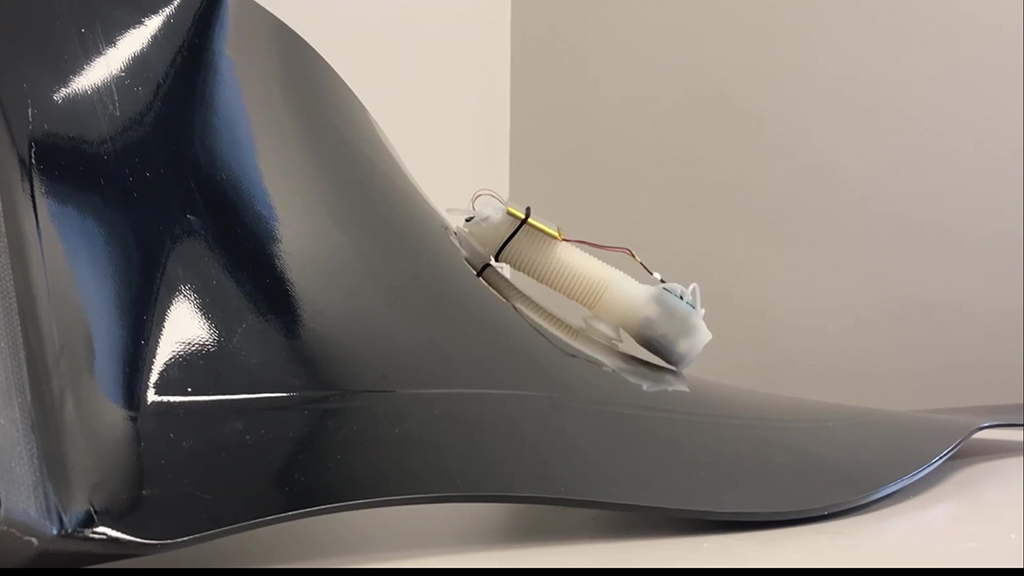

In September, GE Aerospace debuted an inchworm-inspired robot that uses untethered soft robotics technology to move easily through the complex spaces of jet engine parts to detect defects and corrosion. The Sensiworm (Soft ElectroNics Skin-Innervated Robotic Worm) features a sticky, suction-like bottom that allows it to climb and adhere to steep surfaces, while its soft form prevents potential damage to surfaces. Although the technology is still under development, GE says Sensiworm could reduce unnecessary engine removals and downtime.

Dutch robotics specialist Xyrec is working with a major aircraft manufacturer to use its robotics technology to remove aircraft paint and coatings more quickly, safely and cleanly. The company, which operates out of a custom-built facility at Port San Antonio in Texas, is planning to establish several other regional centers in the U.S. by the end of 2024.

Drone Inspections

Drone-based aircraft inspections are continuing to gain acceptance in the MRO industry. Over the last year, several airlines and MRO providers have signed agreements with drone inspection providers and ramped up testing in their operations. Donecle, a major provider of drone-based inspections, completed a €5.6 million ($5.9 million) funding round on Oct. 5.

Korean Air, which has been developing a unique inspection approach using a swarm of multiple drones, was recently awarded maintenance research and development assistance by the South Korean government, and it is working toward obtaining regulatory approval for the technology.

Drones are also gaining traction for defense MRO. In June, Dassault Aviation and the French Armed Forces’ Aircraft Maintenance Division signed an agreement with Donecle to implement its drone inspection technology for Rafale aircraft. The UK Royal Air Force recently began exploring the use of drones for aircraft inspections. Drone startup Near Earth Autonomy is developing drones that could be used for both military and commercial aircraft.