Liquid hydrogen is at the core of Airbus’ exploration of the possibilities for decarbonizing commercial aviation, primarily as a fuel for zero-emission flight. But across Europe and UK, researchers are investigating the potential for also using the cryogenic fluid to cool propulsion systems to improve efficiency and reduce weight.

- GKN’s H2GEAR studying hybrid-electric subregional aircraft

- Airbus’ Ascend assessing potential for flight demonstration

- UK’s FlyZero study highlights cryogenic propulsion potential

Using liquid hydrogen as a zero-emission energy carrier in an aircraft creates the potential to have a cryogenic electrical system, Simon Taylor, director of new air vehicle concepts at GKN Aerospace, told the Emissions-Free Air Transport Through Superconductivity (EFATS) virtual conference on June 10.

Using liquid hydrogen as a zero-emission energy carrier in an aircraft creates the potential to have a cryogenic electrical system, Simon Taylor, director of new air vehicle concepts at GKN Aerospace, told the Emissions-Free Air Transport Through Superconductivity (EFATS) virtual conference on June 10.

Cooling electrical systems down to cryogenic temperatures reduces losses, improves efficiency and increases power density. Cooling them to the point where high-temperature superconducting (HTS) materials can be used further reduces losses and weight.

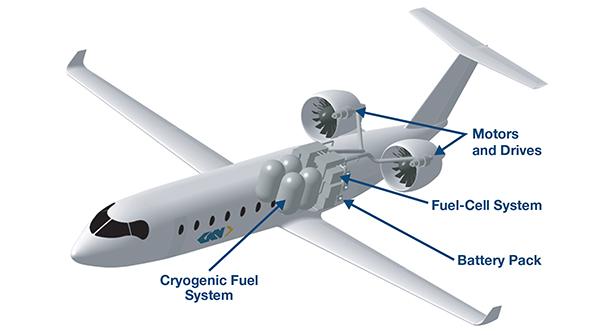

GKN is leading the Hybrid Hydrogen & Electric Architecture (H2GEAR) program, a five-year, £54 million ($75 million) effort supported by £27 million from the UK government via the Aerospace Technology Institute (ATI). H2GEAR aims to develop a hybrid-electric propulsion system for subregional aircraft that uses liquid hydrogen (LH2) and fuel cells and is scalable to larger aircraft.

Electric systems can be refrigerated to cryogenic temperatures using cryocoolers, but these can be heavy and high-maintenance, so H2GEAR is looking at a hybrid-electric system that uses LH2 as both the bulk fuel for propulsion and the heat sink for cooling. The GKN-led consortium includes UK companies Intelligent Energy and Aeristech and the universities of Manchester, Newcastle and Birmingham.

Airbus, meanwhile, in addition to evaluating liquid hydrogen as a possible route to zero-emission commercial aviation by the mid-2030s, is engaged in a research program to explore the potential of cryogenically cooled electric propulsion for large civil aircraft.

The goal of the three-year Advanced Superconducting and Cryogenic Experimental Powertrain Demonstrator (Ascend) project is to determine through ground testing whether the technology offers sufficient potential benefit to warrant flight demonstration in 2028.

“Airbus has launched a very ambitious program to assess and develop liquid-hydrogen aircraft, either to burn hydrogen [in turbine engines] or to use hydrogen through fuel cells to generate electric power,” Ludovic Ybanez, Ascend project lead in the Airbus UpNext demonstrators unit, told EFATS attendees. “If we have liquid hydrogen on board as a cold source, how can we use this to improve the performance of a high-power electric propulsion system for future aircraft?”

There are two main options, Ybanez said. The first is to use cryogenic cooling to increase the performance of conventional electric systems. “The second may be to use high-temperature superconducting technologies to push a breakthrough in propulsion, to dramatically reduce losses, reduce weight and increase efficiency at the aircraft level.”

Cryogenic hydrogen propulsion also is emerging as a promising candidate under the UK government-funded FlyZero study to find a path to zero-emission commercial aviation. The goal of FlyZero is to identify technologies in which the UK must invest if it is to play a leading role in future aircraft programs.

The study was launched in July 2020 and will continue into early 2022, supported by a £15 million grant from the UK government via the ATI. The FlyZero effort involves a team of 85 experts drawn from across the UK aerospace industry and supported by academia, airlines and airports.

The team is looking at a wide range of options to enable zero-emission flight by middle-of-the-market airliners with ranges up to 3,000 nm. This sector covers a significant proportion of the carbon dioxide emitted by commercial aviation, Simon Weeks, FlyZero chief engineer for propulsion, told EFATS.

“The study will run through this year and into next year, but we have started to understand some of the key challenges and think a cryogenic system and the capabilities required to assess, design and integrate this into a safe, certifiable system is a key technology we need to develop for the future,” he said.

In a conventional hybrid-electric propulsion system, in which the energy stored in aviation fuel is converted into electricity by a combustion engine driving a generator, losses throughout the system can result in a transfer efficiency from source to motor of around 83%, Taylor said.

Cryogenic cooling would reduce those losses and, if a superconducting system is used, a transfer efficiency as high as 95% is achievable, resulting in a reduction in system mass, he said, adding: “Superconducting systems are a real enabler for this type of hybrid architecture.”

The E-volution feasibility study conducted by GKN in 2015-18 was a precursor to H2GEAR. This looked at a hybrid-electric airliner configuration with two conventionally fueled turbine engines and a centerline electric propulsor providing drag-reducing boundary layer ingestion.

Detailed studies were performed based on the Fokker 100 with a 1-megawatt electric motor, initially conventional, driving the tail-mounted fan. “What we discovered is that it was really only working with a cryogenic system and preferably with a superconducting network,” Taylor said.

“The study came to the conclusion that our energy carrier [kerosene] was the wrong energy carrier in this case, and that not only do we need a superconducting system, but also we need a cryogen in bulk form so that we could eliminate the cryocooler from the system,” he said.

“We concluded the environmental performance of the aircraft is limited by the fuel, which means we should move to something like LH2, and that to gain the overall efficient benefits we should move to a superconducting system that will use a bulk fuel for both energetic and heat sink potential,” Taylor said.

Kicked off in December and running through 2025, H2GEAR is developing a hydrogen fuel-cell propulsion system with 1.25-2 megawatts of peak power and incorporating a cryogenic electrical machine. LH2 cryogenically cools the motor, heating up and becoming gaseous hydrogen that is consumed in the fuel cells, which generate electrical power to drive the motor.

To understand the integration needs, the team has developed a synthesis aircraft concept with two independent and segregated propulsion systems, from tanks to motors, driving aft-fuselage ducted propulsors. This is a small, 500-nm-range subregional airliner.

GKN sees the configuration as a way to move stepwise from a cryogenically cooled conventional electrical system to a partial superconducting and eventually fully superconducting system. “What that enables us to do is focus on the cryogenic network, at least to start with,” Taylor said. “That will support the certification and safety investigations and enable, in parallel, the investigation and development of a superconducting-rotor or -stator machine to take the technology to the next level.”

For Airbus and the Ascend project, the first step was to assess the maturity of cryogenic technology in ground applications, particularly magnetic resonance imagers, particle accelerators and power transmission. The second step, Ybanez said, was to launch collaborative R&D projects with the main players in this technology, including the ASuMED superconducting motor demonstrator. The third step was to launch projects within Airbus to assess the feasibility of the overall system at the aircraft level.

“We think that some technologies are mature on the ground, like cables and current leads for cryogenic systems,” Taylor said. A second family of technologies seems less mature, including superconducting electric motors and cold power electronics.

“We saw some mature technologies, also potential at the technology level. The question now is can we adapt these technologies to aircraft requirements to give a strong recommendation on their use at the aircraft level to enable electric propulsion?” Ybanez said.

At the component level, cryogenic and superconducting technologies can increase power density by a factor of 2-3, increase current and reduce voltage, improve power-train efficiency beyond 98% and enable new capabilities such as fault current limiters.

“The question is: How can we assess the impact at the aircraft level?” he said. “The most favorable option would be to embed liquid hydrogen on board. But what topology do we want to assess? What aircraft architecture would be interesting with these technologies?”

Of the potential benefits, two are potential game changers at the aircraft level, Ybanez said. “The first is weight. It depends on the length of the cables, but we believe we can decrease weight by a factor of 2-3 depending on the topology.

“The second is voltage. Embedding high voltage into an aircraft is very difficult,” he continued. “If we can demonstrate we can reduce the losses, increase the current and reduce the voltage, we can increase the feasibility [of] and interest in these technologies.”

Megawatt-scale propulsion systems using conventional electrics must operate at kilovolt levels to minimize currents and cable weight, which introduces issues such as partial discharge at altitude. Ascend is targeting 300-500 volts. “I hope we will be able to demonstrate 300 volts. That could be a game changer for electrification of aircraft,” Ybanez said.

The goal of Ascend is to identify potential showstoppers and either evaluate how to overcome them or decide that the technology is not mature enough for flight and stop the demonstration. “We need to integrate all the components and technology to be able to assess and confirm the potential,” he noted.

Ascend will develop several “bricks” using ground technologies. First is a DC distribution network with cryogenically cooled current leads, 10-m-long (33-ft.) superconducting cables and fault protectors. Second is a cold motor control unit with cryogenic power electronics. Third is the superconducting electric motor.

The 500-kW power train will use liquid hydrogen for cooling only, not as fuel. “For this first step, we don’t want to use hydrogen directly; we just want to demonstrate we can master the technology to control temperature and be able to extract losses and show the potential at a system level,” Ybanez said.

Testing of the demonstrator in Airbus’ E-Aircraft System House in Ottobrunn, Germany, is planned to be completed by the end of 2023. The results will be used to validate models of the system bricks that then can be scaled from 100 kW to multimegawatt power levels for use by Airbus in different aircraft studies.

If Ascend Phase 1 testing based on ground technologies is successful, a Phase 2 from 2024 to mid-2025 would develop aircraft-specific technologies and the power train for a target aircraft. Phase 3 in 2026-28 would flight-test the power train. “I really think this technology has a huge potential, and this is a very interesting opportunity to enable high-power electric flight,” Ybanez said.