In the year since COVID-19 morphed into a global pandemic, OEMs and operators have focused increasing attention on the business aircraft cabin environment. Of particular concern is keeping cabin air pathogen-free.

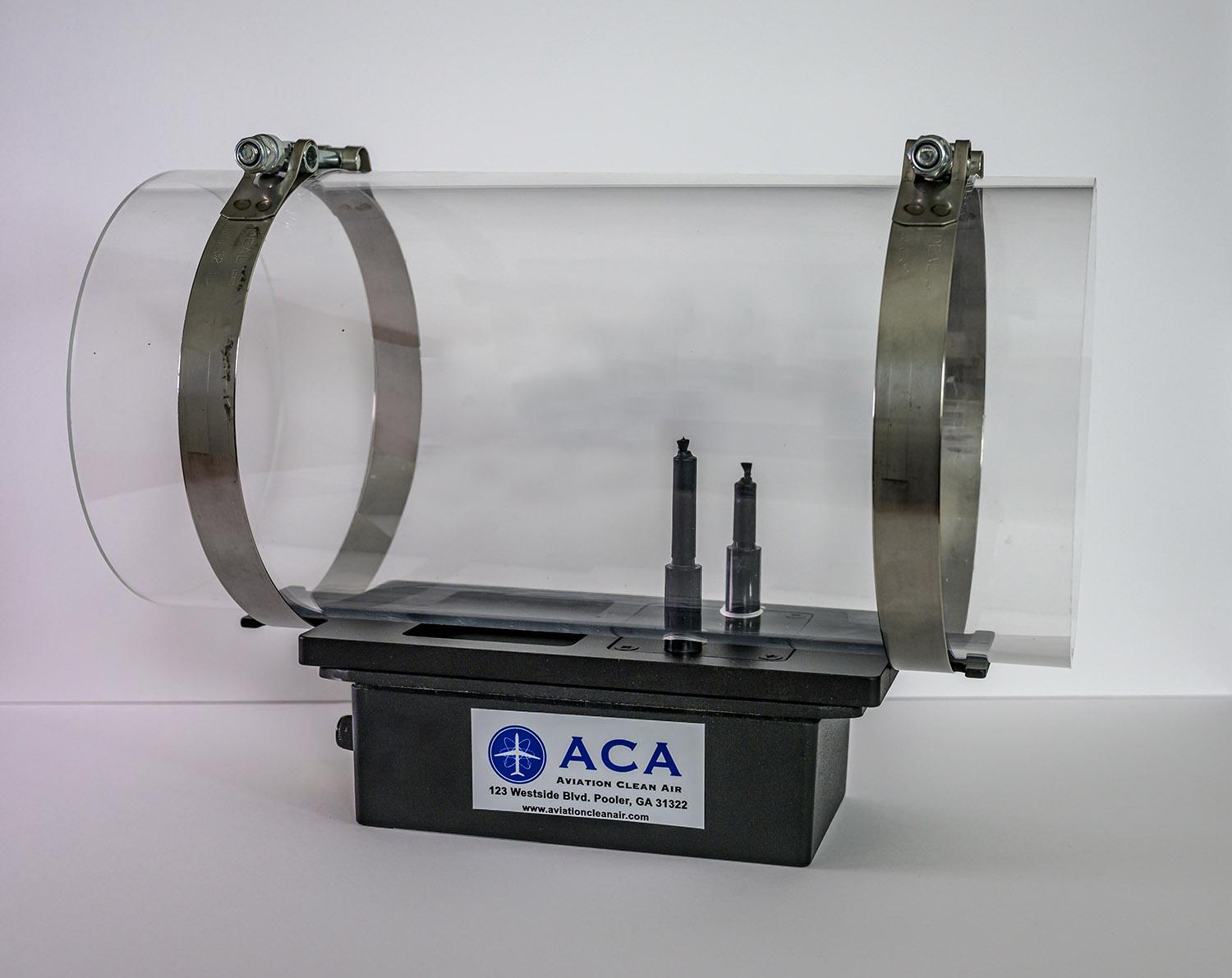

The corporate aviation world is, in fact, moving ahead with the adoption of new technologies that will keep cabin occupants safe by keeping the air they breathe pathogen-free. One such technology is Aviation Clean Air’s (ACA) NeedlePoint Bi-Polar Ionization (NPBI). Installed in an aircraft’s environmental control system (ECS), activation begins when the ECS is switched on and air flows into the cabin and cockpit through the air ducts.

“Once activated, it emits cold plasma, allowing positive and negative ions to attach to water vapor molecules in the cabin air, causing a molecular reaction that neutralizes gases, spores, viruses and bacteria,” explains Jonathan Saltman, a partner at ACA. “Tests we have conducted have proven that NPBI is effective against several bacteria types and viruses--including COVID-19--as well as odors and static electricity.”

Laboratory testing, concluded on Jan. 5 and carried out by Innovative Bioanalysis of Costa Mesa, California, revealed that within 90 min. of activation, NPBI achieved a neutralization and reduction rate of 99.9999% of COVID-19 within the cabin, Saltman reports. He adds that on Feb. 12, further testing by the laboratory showed a similar rate of neutralization and reduction for influenza A and B strains, as well as rhinovirus, E. coli, MRSA (methicillin-resistant Staphylococcus aureus) and aspergillus.

According to Saltman, most aircraft OEMs are now offering the ACA solution. “In excess of 60 STCs have either been issued or are ‘in-work,’” he reports. “Depending on the aircraft, installation takes about 50-100 man-hours, largely due to wire changes required for the ECS.

“In today’s world, cabin air quality has never been more important,” says Brian Rohloff, senior vice president of customer support at Textron Aviation. “The safety and well-being of our customers is our priority, and we want to ensure they can fly responsibly as the pandemic evolves.”

He notes that on Feb. 1, Textron Aviation announced that it is offering NPBI, for retrofit, at Textron Aviation Service Centers. The announcement followed the first installation of the system carried out by the aircraft OEM in late 2020.

The system, Rohloff points out, is approved for installation on the Cessna Citation Latitude and Sovereign series models, the Citation Excel/XLS/XLS+ series and Cessna Citation X jets, as well as Beechcraft King Air 300-series turboprops, with continued development planned for other Textron Aviation models.

“Upon activation, the ACA NPBI System takes effect within minutes and is designed to constantly decontaminate the cabin’s interior including the air and surfaces,” adds Rohloff.

Asked if ionization-based systems should be considered the leading cabin air purification technology available today, Rohloff says that while they are a “great choice”--in addition to other systems, such as traditional HEPA filters--it depends on the customers’ needs. “When it comes to cabin air management and sanitation efforts, there is no one-size-fits-all solution.”