This article is published in Business & Commercial Aviation, part of Aviation Week Intelligence Network (AWIN), and is complimentary through May 07, 2024. For information on becoming an AWIN Member to access more content like this, click here.

Piper Archer training aircraft operated by a flight school in California, not affiliated with UND.

Industry and FAA testing thus far has revealed no “smoking gun” to explain the engine wear issue experienced by the University of North Dakota (UND) flight school last year after it switched to using unleaded aviation gasoline, a Lycoming Engines executive said April 23.

UND’s John D. Odegard School of Aerospace Sciences in Grand Forks switched from using 100 Low Lead (100LL) avgas to Swift Fuels UL94 unleaded fuel in June 2023. But it switched back to using 100LL last October after finding abnormal exhaust valve recession in some of the engines powering its fleet of 75 Piper Archer, 14 Piper Seminole, and five Robinson R44 aircraft, all with Lycoming piston engines.

UL94 is a 94+ motor octane number unleaded avgas that Swift Fuels has produced since 2015. It is the highest octane-rated unleaded fuel available as the FAA and industry pursue development and supply of a 100-octane unleaded fuel that can work across the portion of the U.S. piston aircraft fleet with high-compression, octane-demanding engines.

As of this month, Lycoming, the FAA, Swift Fuels, and the university have not been able to determine the cause of the engine wear issue at UND, Jennifer Miller, Lycoming Engines senior director of engineering, told an online briefing of the Eliminate Aviation Gasoline Lead Emissions initiative.

“We were really put back on our heels with this, given the ... years of fielded UL91 and UL94 experience [and] hundreds of thousands of flight hours,” Miller said. “We have no reason to believe this is a safety-of-flight issue for other operators. Lycoming does not have a history of valve seat recession. Lycoming quickly composed a list of primary and secondary hypotheses, also knowing full well that the circumstance could simply be the perfect storm of small contributions.”

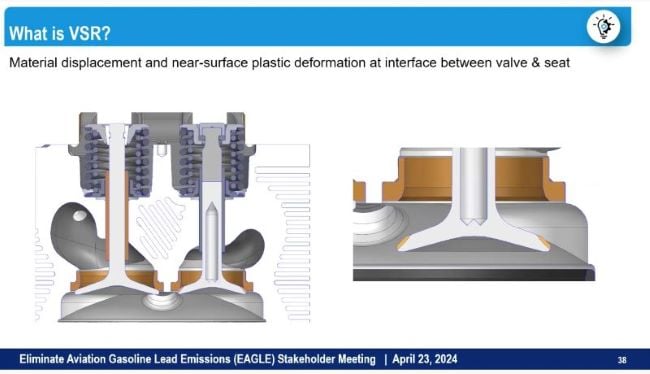

The valve seat in an internal combustion engine is the surface against which an intake or exhaust valve rests during the engine operating cycle when that valve is closed. Valve seat recession (VSR) refers to accelerated seat wear.

A graphic presented during the briefing depicts valve seat recession. Credit: EAGLE

“VSR occurs when the hammering of the valve on the seat during operation results in material displacement and deformation of the seat, resulting in a condition where the valve and seat interfaces fail to seal,” Miller explained.

All of the aircraft in the UND flight training fleet have “parallel head, standard 8.5:1 compression engines that have plenty of detonation margin on UL94,” Miller said. About 28% of the fleet experienced VSR after switching to UL94. The first case presented itself in August 2023 and was only found after engines had operated for a minimum of 400 hr.

“While clearly the principal cause is that in the absence of lead there is nothing in the fuel to provide a cushion between the seat and the valve, there are other aggravating factors at play here,” Miller said.

“Yet our investigation has revealed no smoking guns. The engines, the cylinders are conforming; the valve seats and timing are conforming; the fuel was conforming to the spec and not contaminated.”

She added that UND pilots flew the aircraft in accordance with their respective operating handbooks, referencing the Archers and Seminoles specifically.

“Currently our leading hypothesis is related to aromatic content in the fuel and the thermal impact on the valve seat,” Miller said. “Lycoming and the FAA are pursuing aromatic sensitivity testing to validate or invalidate that theory. I want to stress that this is just a hypothesis and that not all parties are in agreement. What we do know is that this is isolated to UND. We do not believe it is a safety-of-flight issue because it is discoverable.”

The FAA, Lycoming, Swift Fuels and UND are still collaborating to isolate the cause of the engine wear issue, Miller said. They are also keeping other users of UL94 informed of their testing progress.

Comments