Shaping The Future Of Engine MRO With Innovation And Technology

As flying activities regain normalcy and return to their growth trajectory, MRO shops aiming to ride the next wave of growth and capture new opportunities are turning to technology and innovation to transform their operations and sharpen their competitive edge. ST Engineering’s Commercial Aerospace shares how its engine MRO business harnesses the power of innovation and continuous improvement across technology, process and operations, and sustainability to capture greater value for itself and its customers.

Digital solutions

To meet the ever-changing demands of the fast-paced aviation industry, ST Engineering is transforming its engine shops into a digital environment through the development of in-house applications to scale up and improve its solution offerings.

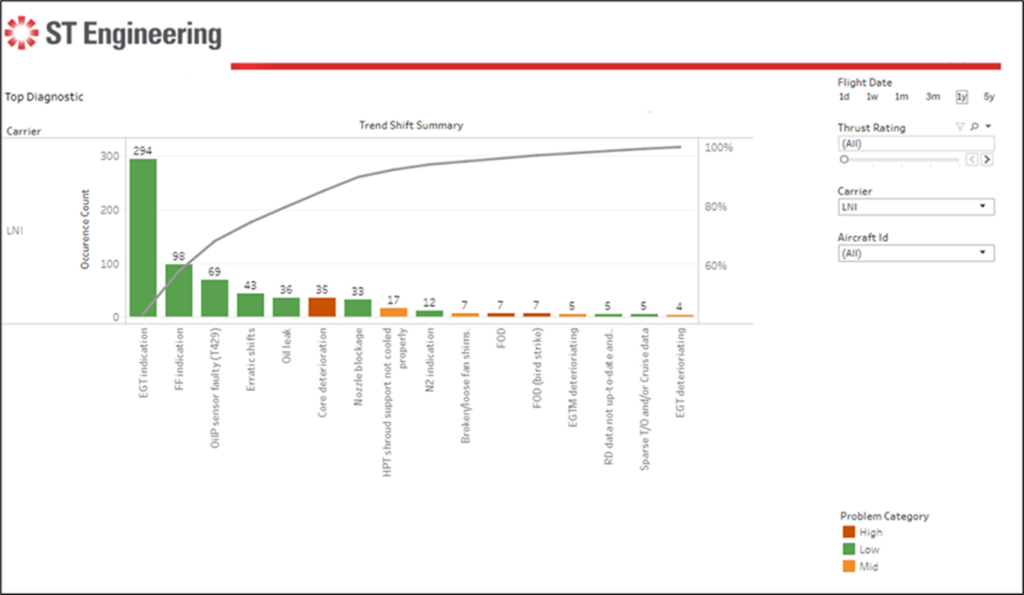

One such application is an Engine Health Monitoring system which integrates AI and machine learning for predictive maintenance, flight optimization and data analysis. Such a solution makes having a dedicated engineer to sieve through millions of data points to provide an accurate prognosis of engine health a thing of the past.

Just as importantly, the system assists customers to make informed decisions based on the analyzed data. With completely customizable dashboards, customers can easily retrieve information tailored to their needs to optimize maintenance planning, fleet management and engine reliability.

On top of developing customer-facing applications, ST Engineering has also improved its internal process efficiency by implementing a fully integrated, paperless solution for work process documentation.

The paperless solution, Engine Visual Information System (ENVIS), is developed in-house and accepted by the U.S. Federal Aviation Administration, European Union Aviation Safety Agency, Civil Aviation Administration of China and Civil Aviation Authority of Singapore. With ENVIS, ST Engineering has increased oversight of shopfloor processes and access to data analytics, helping it to manage quality, turnaround time and engine costs more efficiently. The solution has also effectively eliminated hardcopy records and incorporated mistake-proofing documentation in its workshops. Engine records can now be accessed digitally anywhere at any time, leading to increased customer satisfaction.

Automation

Besides digital solutions, automation and robotics also play an important role in ST Engineering’s engine MRO process to solve complex challenges and eliminate repetitive and laborious tasks. Its co-developed Intelligent Mapping and Profiling (iMAP) engine blade mapping system is a fully automated solution capable of measuring blade weight and chord width and sorting them accordingly while minimizing human error.

Sustainability

ST Engineering is determined to reduce its carbon footprint and dependence on non-renewable energy sources. From deploying solar panels atop its aerospace facilities to embracing digitalization for paperless work, its Commercial Aerospace business proactively searches for ways to minimize its impact to the environment. Its most recent initiative is to develop a better understanding of the correlation between test cell performance and shop processes. Through greater clarity of workscope and material replacements, ST Engineering is finding the method for optimizing the amount of testing required with the objective of reducing fuel consumption.

Shaping the future

To better support its customers, ST Engineering has continuously pursued excellence in innovation and continuous improvement, overcoming many challenges along the way. By strengthening its processes with initiatives across technology, operations, and sustainability, its engine MRO business is able to continuously augment its value propositions for engine operators regionally and globally. As it continues in its journey of innovation and continuous improvement, ST Engineering is helping to shape a future of engine MRO that is characterized by technological advancements and sustainability.

Learn about the breadth and depth of ST Engineering’s engine MRO capabilities: https://www.stengg.com/en/aerospace/aerospace-mro/engine-services/